The importance of a good union in the aluminum/copper connection in a transformer.

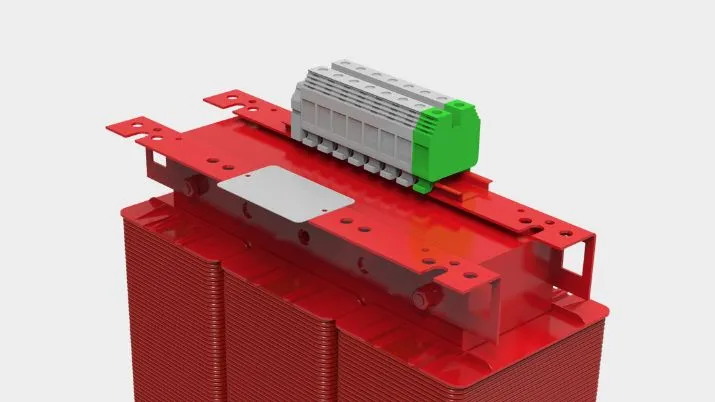

One of the main problems that exist in transformers made with aluminum windings is the connection issue. Most of the breakdowns that occur are due to a bad union between the aluminum conductor and the strips or plates that are delivered to the customer to make the transformer connections.

A good union between aluminum and copper must be guaranteed, since they are two metals that cannot be directly welded and joined without applying intermediate techniques and materials that make this union safe.

The main problems with aluminum is that if it oxidizes aluminum oxide is not a conductor, which causes overheating in the joining area, which ends up causing them to burn. This does not happen with copper transformer joints, snce the copper oxide is conductive and does not reduce the effective section.

To solve this problem POLYLUX makes the joints with welding with special alloys for copper/aluminum joints or bimetallic joints for flat bars. After appling a sealing of these joints with coatings and varnish impregnations, which guarantee the absennce of oxygen, preventing oxidation.

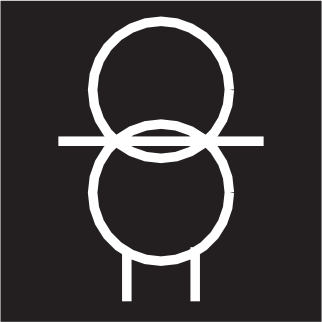

Figure A. Not welded = Wrong

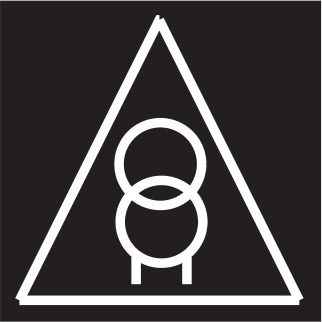

Figure B. Welded = Good

Be wary of direct pressure joints to a terminal (Fig.A) or soldering with conventional tins, which will, in the long run, cause breakdowns and malfunctions in the installations.

You may also be interested in

Share this tutorial

Related tutoriales

Newsletter

RECEIVE OUR NEWS IN YOUR E-MAIL