TECHNICAL DOCUMENTATION

Do you need technical documentation for your equipment?

In the product datasheet you will find drawings and certifications that you can download in PDF, DXF and STP format.

Access all the documentation for your equipment by searching for the reference.

MAINTENANCE OF TRANSFORMERS

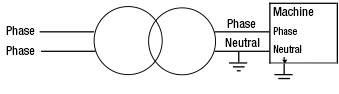

Dry type transformers, unlike oil-filled transformers, offer advantages and ease of maintenance. However, they require a series of checks to maintain the service life of the transformer. The frequency of these checks depends on the environmental and operating conditions of the transformer.

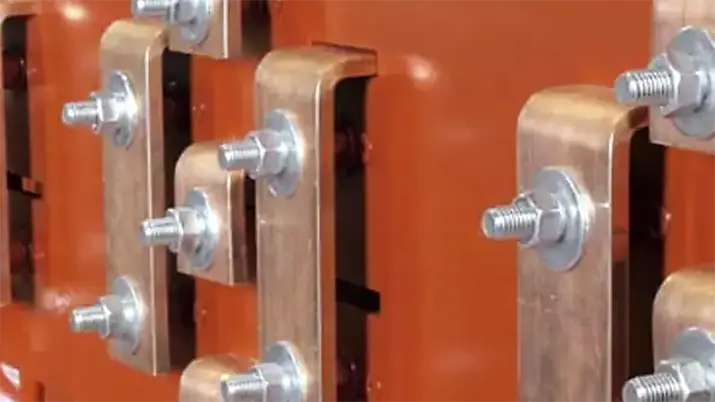

It is also important to check the connection of the wires to the connections and to make sure that the terminal bolts are still tight. If not, all connections should be retightened.

Learn more about how to protect a transformer with our online resources.

FAQ’s

Do you have a problem with your equipment?

Explore these frequently asked questions and technical doubts and find the answer you need. Or contact us.

WE ARE AT YOUR DISPOSAL

Do you need any other technical support?

Contact our technical support team. Send your query using the form below or contact us by phone.